I had a few questions for Natalie Franzén, Baltic Offshore’s CEO

“How we can manage more cable breaks in the Baltic Sea” (in Swedish) set the tone for the opinion piece recently written by Tykoflex CEO Richard Petersson Wigh together with Natalie Franzén, CEO of Baltic Offshore. Handling cable breaks is an important part of preparedness to ensure that critical infrastructure continues to function or is quickly repaired in case of failure. In the interview series “I asked a few questions to…” Richard meets with people who have expertise in the field. First up is co-author Natalie Franzén, CEO of Baltic Offshore.

We would like to take this opportunity to thank Natalie for making time to participate in an interview, which highlights the fantastic collaboration that exists between the actors who contribute to the strong repair capability we have in the Baltic Sea, including both suppliers and competitors. This is not something that can be taken for granted or solved through contracts – it is the people behind it who make it possible.

Questions to Natalie Franzén

Q: Can you briefly tell us about Baltic Offshore and your role in relation to cable breaks?

A: Baltic Offshore has a number of standby agreements with network owners. This means that we stock spare materials and are on call around the clock, every day, to repair cable faults. Of course, we also repair cable faults for customers who do not have standby agreements. The difference is that in those cases, the response time is not pre-determined, but instead agreed upon case by case.

Q: In your assessment, what is the most common cause of cable breaks, and has this changed over time?

A: Many cable breaks are caused by natural factors such as weather conditions and seabed characteristics, and sometimes by external factors such as anchors and fishing gear. Not all cable breaks are reported in the news, and the causes of the breaks we repair remain mixed.

Q: What is required for a successful repair?

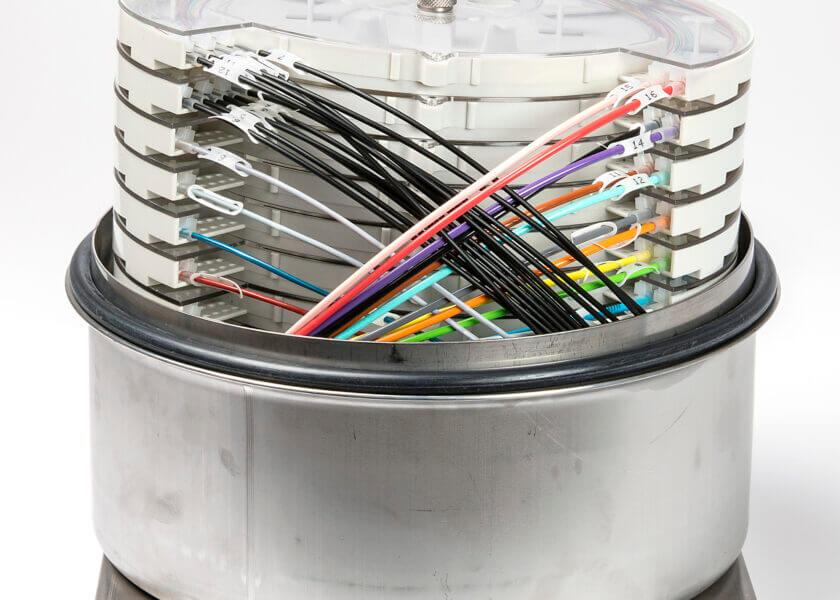

A: A properly equipped vessel and the right expertise that is always on standby for rapid intervention. A properly equipped vessel means being able to handle the submarine cable but also having access to spare cable and joints. The right expertise is a combination of different positions, training, and experience required to handle everything a repair at sea involves.

Q: How do you view the recent repairs and the speed with which they were carried out?

A: The repair itself almost always takes the same amount of time. The factors that affect the timeline are mainly weather conditions. In the most recent repair, we also had to take into account the police investigation that was initiated. I believe we could have saved time from the cable break to the restoration of traffic, but I also think all parties involved are aware of this and have tried to follow up in a good way through meetings and dialogue. After all, no one really knew how to handle a situation where there was both a cable fault and a suspected crime at the same time.

Q: How do you view the need for a contingency plan to ensure sufficient capacity to handle a large number of simultaneous incidents?

A: In the Baltic Sea there are currently sufficient resources to repair several cable faults simultaneously and consecutively. However, the question is how many and how often we can manage. We are looking at carrying out such simulations together with our customers and suppliers, but also with authorities, in order to create mutual understanding and, where possible, to increase efficiency and even find ways to benefit from each other.

Q: Is there a shortage of vessels for cable repair?

A: No, not at present. However, we must safeguard the Swedish cable repair vessel and ensure the same conditions as in our neighboring countries. That is not the case today. This concerns both our competitiveness and Sweden’s preparedness in times of crisis and war.

Q: How do permits work today for repairing and laying cables—does this limit you in any way?

A: Installing new cables has become a long process, sometimes as long as three years. Here we must improve. A permit for a new installation is handled by the same authorities multiple times, and the process has become very drawn out in recent years. Continuing to strengthen infrastructure and create robust networks is crucial to being able to handle multiple breaks simultaneously.

Q: What skills are required to repair a cable, and how can they be maintained?

A: Marine competence is required for navigation and vessel operations, cable handling competence is required for managing the submarine cable, and splicing and measurement competence is required for the specific cable type being repaired. We can provide training for many parts, but when it comes to handling, long experience is essential. Competence is not only decisive for a successful repair outcome but also for the most important factor of all—safety.

Q: How easy, or difficult, is it today to recruit people with the competence and willingness to work at sea?

A: We believe that in the long run it may become more difficult to recruit, but at the same time we see progress in education that enables career changes into shipping later in life. We think this is an important factor, since today people prioritize family time differently than before, and later in life may see an opportunity to work at sea. Those with solid experience, for example in fiber splicing and measurement, or in construction and civil engineering, have good potential—combined with seafaring skills—to become valuable employees with us.