What is OPGW?

A guide to OPGW

What is OPGW?

OPGW stands for Optical Ground Wire, a type of cable used in overhead power lines that not only provides grounding and lightning protection, but also houses optic fibers for data transmission. When people ask, “what is OPGW?” they are often curious about how a single cable can serve such a dual purpose. This article will answer that question.

Purpose

The purpose of an OPGW cable is twofold:

Firstly, it protects power lines from lightning strikes by acting as the shield wire at the top of the transmission tower.

Secondly, it provides a secure and robust pathway for fiber optic communication. This makes it an essential component for utilities looking to expand their data networks along existing transmission infrastructure.

To make full use of the communication network, there can be intersections where the OPGW cable splits into two separate branches to continue along different routes. Additionally, a “drop cable” may be lowered from one of the towers to connect a nearby community or facility to the fiber network for various purposes, such as internet access or monitoring systems. Some of the fibers are used for the power transmission companies own needs, and some fibers are often rented to other companies.

OPGW cable splits into two separate branches to continue along different routes. Additionally, a “drop cable” may be lowered from one of the towers to connect a nearby community or facility to the fiber network for various purposes, such as internet access or monitoring systems. Some of the fibers are used for the power transmission companies own needs, and some fibers are often rented to other companies.

OPGW cable designs

An OPGW cable typically consists of several steel wires twisted around a central steel wire. One, two or three of the wires has been exchanged for a hollow steel tube that contains the optical fibers. These fibers enable high-speed communication, while the surrounding wires protect the cable from lightning and conduct any fault current safely to the ground. This way of protecting the fibers inside a steeltube is sometimes refered to as Fiber in Metal Tube, or “FIMT”.

How is an OPGW cable installed?

OPGW cables are installed at the top of transmission towers (pylons), replacing or supplementing the traditional ground wire. The process usually involves securing the cable reels at one end, carefully unwinding the cable across the transmission line route, and lifting it into place on each tower. The cables themselves often come in specific reel lengths, and these lengths are strategically chosen so that splicing can be done on a tower, rather than between towers. Once in position, the cable is clamped firmly to the tower structure to handle mechanical stresses such as tension, wind load, and ice buildup. It is crucial that the installation team follows best practices to avoid damage to the fibers during pulling and stringing operations.

How are OPGW cables spliced?

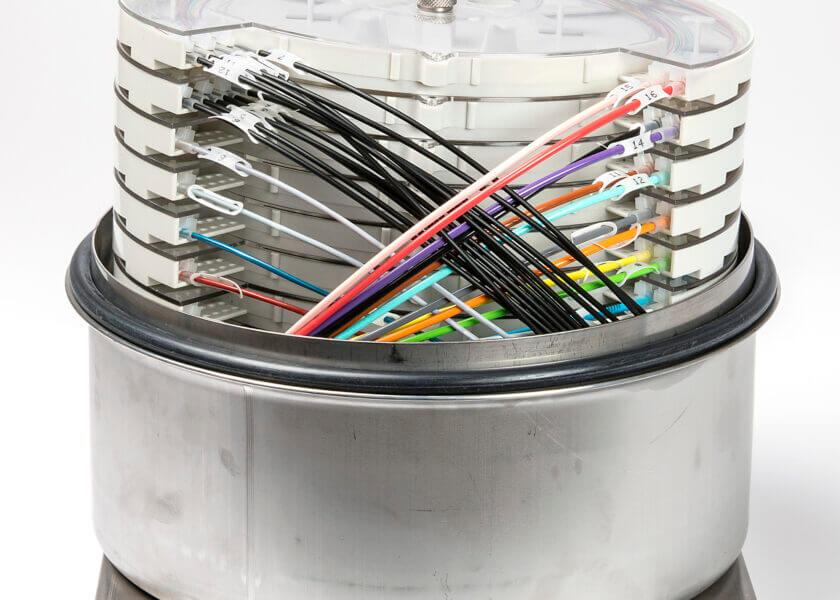

If you are still wondering, “what is OPGW?” and how it is maintained, one of the most important steps is splicing the optical fibers. Splices occur inside specialized enclosures, often called joint closures or splice closures. An example is the Tykoflex T240 joint closure, designed with features such as strain relief and torsion protection for the cable entering the box. Inside, a series of organizers and trays manage the fiber strands. The cable entries are sealed to protect the fibers from moisture and dust. Technicians carefully strip the cable to expose the fibers, then fuse them together using precision splicing equipment. This creates a low-loss connection between the fibers, ensuring signal integrity.

enclosures, often called joint closures or splice closures. An example is the Tykoflex T240 joint closure, designed with features such as strain relief and torsion protection for the cable entering the box. Inside, a series of organizers and trays manage the fiber strands. The cable entries are sealed to protect the fibers from moisture and dust. Technicians carefully strip the cable to expose the fibers, then fuse them together using precision splicing equipment. This creates a low-loss connection between the fibers, ensuring signal integrity.

Branching

The joint closure also provides the possibility to branch out, allowing an OPGW cable to split toward different routes. Moreover, the joint closure offers the opportunity to “drop” a cable from the tower to serve nearby communities, data centers, or other network expansions. By now, you should have a clear understanding of what is OPGW and why it is an integral part of modern power and communication networks.

What to Consider When Choosing an OPGW Joint Closure

Selecting a reliable OPGW joint closure is critical to ensuring reliable, long-term performance and minimizing maintenance and repair needs. When evaluating different options, prioritize manufacturers and products with a proven track record of at least 30 years in the field. This indicates both practical experience and a history of successful deployments, reducing the likelihood of unforeseen issues down the road.

Technical lifespan

In addition to a strong track record, look for a closure that is specifically designed to maintain its performance for up to 50 years, reflecting the manufacturer’s stated technical lifespan. This longevity often comes from rugged construction materials, such as stainless steel, which can withstand challenges including UV radiation, corrosive pollutants, extreme temperature fluctuations, and even shotgun shots. Stainless steel enclosures are much less prone to degradation over time compared to closures made of plastic, ensuring that the cable splices remain protected in harsh outdoor conditions.

technical lifespan. This longevity often comes from rugged construction materials, such as stainless steel, which can withstand challenges including UV radiation, corrosive pollutants, extreme temperature fluctuations, and even shotgun shots. Stainless steel enclosures are much less prone to degradation over time compared to closures made of plastic, ensuring that the cable splices remain protected in harsh outdoor conditions.

Water proof rating

Another critical feature is the waterproof rating. A closure certified to IP68 with 20 meter water head offers substantial more protection against moisture ingress than the standard 1 meter water head. Over the course of time, environmental factors will degrade the closure’s sealing materials and thus it’s sealing performance. Starting with an extra high water column of 20 meters will grant peace of mind that the sealing performance is adequate even at the end of the system’s technical life.

environmental factors will degrade the closure’s sealing materials and thus it’s sealing performance. Starting with an extra high water column of 20 meters will grant peace of mind that the sealing performance is adequate even at the end of the system’s technical life.

Flexibility

Beyond durability, it is also vital to consider future flexibility. A well-designed OPGW joint closure should allow for the addition of extra cables, such as branching OPGW or drop cables, at a later stage. This adaptability is especially important for utility networks that may need to expand or redirect fiber connections as service demands grow. By choosing a closure with multiple cable-entry ports and easily modifiable configurations for the number of fibers and cable types, you set the stage for seamless upgrades, preventing costly overhauls or replacements later on.

What is ADSS?

ADSS is also an aerial cable and the abrevation means All-dielectric self-supporting cable. It is used in pole-mounted installations. The optical fiber itself is dielectric and is not affected by electric fields generated bytransmission lines, lightning induction, external noise or crosstalk. Fiber in ADSS cables is usually single-mode fiber with low transmission loss, which allows long-distance transmission with high speed and capacity.

OPGW is commonly used in the backbone of the network whereas ADSS is used as the “nerves” reaching out from the spine and to each community.

Other parts of the power transmission system

The OPGW cable is often only a little part of the entire power transmission system, some parts might be buried in the ground, some underwater, and some suspended in the air. The transmission system operator often awards several suppliers to install different parts of the system.

Tykoflex offers joint closures for all parts of the transmission system:

- Seaflex is our product group for submarine cables.

- Beachflex is our product group for the landing point where the submarine cable meets the terrestrial cable.

- Wind power

- Telecom backbone

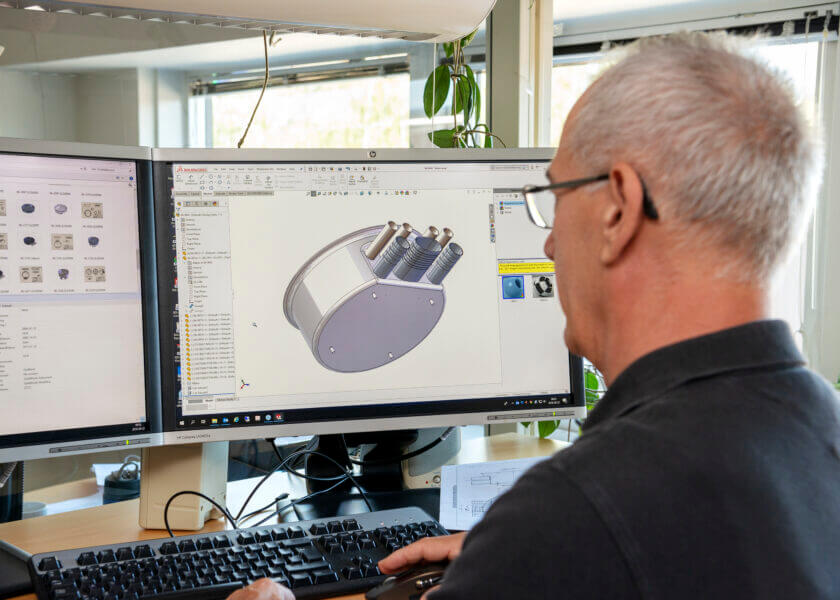

Tykoflex OPGW Joint closure T240

To learnt more about OPGW, ADSS and how the joint closures can help you build a reliable and flexible system, please contact Stefan Örjes: